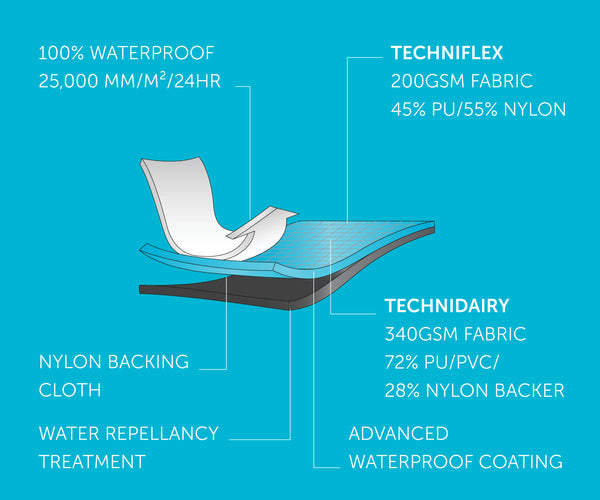

1. The fabric:

Techniflex is made from 200gsm fabric constructed of 45% PU and 55% Nylon. PU is the secret sauce here, adding flexibility and comfort while keeping you bone-dry.

Technidairy is made from 340gsm fabric constructed of a 72% PU/PVC mix and 28% Nylon backer. PVC (Polyvinyl Chloride) is a time-tested champion at keeping the rain out and excels at resisting acids and chemicals. PU creates the softness and flexibility in the material.

2. The stretch

Due to having more PU, and no PVC, the Techniflex has the edge when it comes to stretch and flexibility; stretching up to 100% of its original size without distortion.

3. The weight

Although both garments are considered lightweight, the PVC component of Technidairy means it’s slightly heavier at 340gsm vs Techniflex at 200gsm.

4. The function

A weapon in the dairy shed, Technidairy is designed to stand up to all the acids and chemicals, whereas Techniflex is designed for more general farm activities. Technidairy even boasts an antimicrobial treatment, keeping the inside fungi free.

The Techni ranges are one of the most long-standing and faithful in the Betacraft wardrobe. Designed in 1995, they’ve been tested and proven in NZ’s most extreme conditions for decades. With many years of fabric improvements and developments, year after year, Flex and Dairy are Betacraft favourite’s.

So the million dollar question; would you benefit from having a garment that is more resistant to acids and chemicals?

Yes? Technidairy is for you

No? We suggest going for the stretchier, lighter weight option, Techniflex.